Introduction:

Carbon steel end caps are essential components in piping systems across various industries. From their materials to their applications, there’s much to explore about these crucial elements. Here’s a comprehensive Q&A to delve into the world of carbon steel end caps.

1. What are carbon steel end caps, and how are they made?

Carbon steel end caps are fittings used to seal the ends of pipes. They are crafted from carbon steel, an alloy of iron and carbon, through processes like forging or machining. Carbon steel provides durability and corrosion resistance, making it ideal for various industrial applications.

2. What are the primary functions of carbon steel end caps?

Carbon steel end caps serve two primary functions: they seal the ends of pipes to prevent leaks and contamination, and they provide access for inspection, maintenance, or cleaning of the pipeline system.

3. What industries commonly use carbon steel end caps?

Industries such as petroleum, chemical processing, natural gas, shipbuilding, and construction extensively use carbon steel end caps in their piping systems.

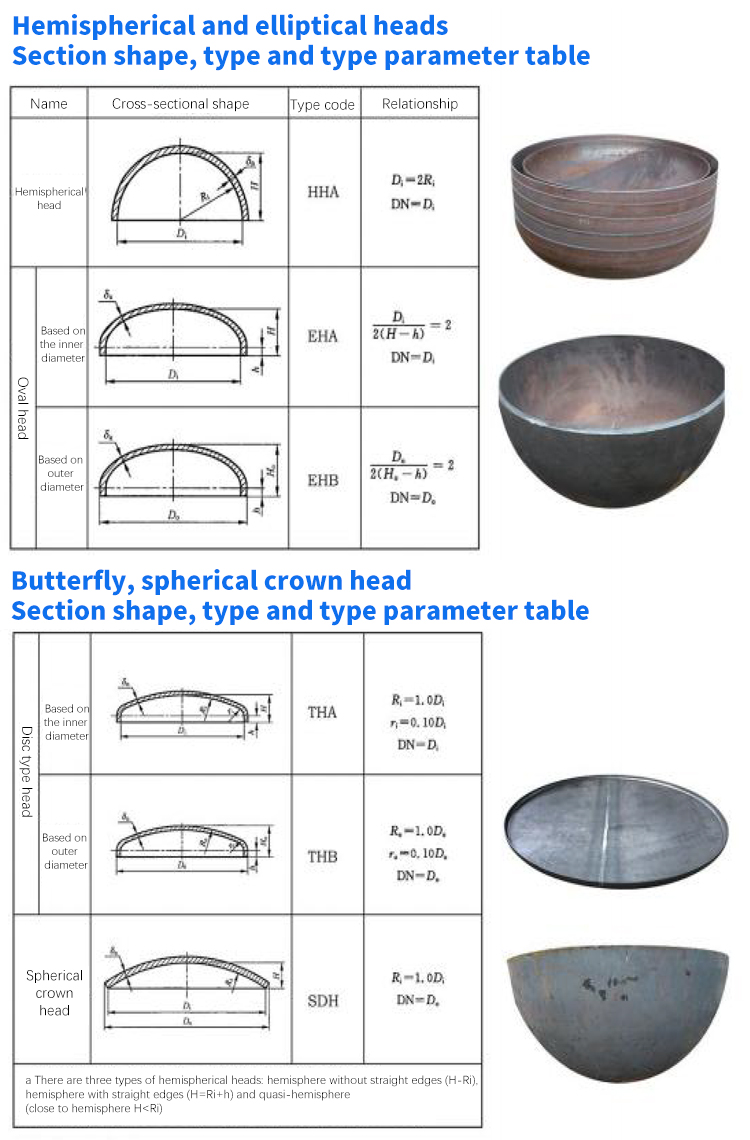

4. What are the different types of carbon steel end caps?

Carbon steel end caps come in various types, including buttweld end caps, socket weld end caps, threaded end caps, and flanged end caps. Each type caters to specific piping requirements and installation methods.

5. How do you select the right carbon steel end cap for a piping system?

Several factors influence the selection of carbon steel end caps, such as pipe size, pressure rating, temperature, material compatibility, and installation method. Consulting with engineers or referring to piping standards can aid in making the appropriate choice.

6. What considerations should be made during installation?

During installation, ensure proper alignment and welding techniques to prevent leaks or structural weaknesses. Additionally, adhere to safety protocols and industry regulations to maintain the integrity of the piping system.

7. What are the advantages of using carbon steel end caps?

Carbon steel end caps offer excellent strength, durability, and corrosion resistance, making them suitable for demanding industrial environments. They also provide cost-effectiveness and ease of installation compared to alternative materials.

8. How do you maintain carbon steel end caps for optimal performance?

Regular inspection, cleaning, and maintenance are essential for prolonging the lifespan of carbon steel end caps. Addressing any signs of corrosion, damage, or wear promptly can prevent costly repairs or replacements in the future.

9. Are there any limitations or challenges associated with carbon steel end caps?

While carbon steel end caps offer numerous benefits, they may be susceptible to corrosion in certain environments, requiring additional protective measures or alternative materials in corrosive applications.

10. What advancements or innovations are shaping the future of carbon steel end caps?

Advancements in manufacturing processes, such as advanced coatings or alloy compositions, aim to enhance the performance and longevity of carbon steel end caps, catering to evolving industry demands and environmental considerations.

Conclusion: Carbon steel end caps play a crucial role in ensuring the integrity and functionality of piping systems across diverse industries. Understanding their properties, applications, and maintenance requirements is essential for maximizing their performance and longevity in industrial settings.

For more questions please contact us

more content

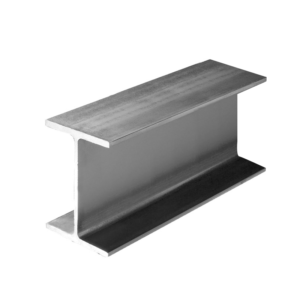

H-Beam

Galvanized Coil